Research and education

Area, strategic goals and metrics

Target 12.4

High‑quality and eco‑friendliness of our products, including a process for the development of new products that respects safety and the environment throughout its life cycle

The Balakovo branch developed and implemented a process for the conversion of phosphogypsum and fluosilicate acid to obtain highly demanded products

Development of an energy‑saving technology for the production of complex granular fertilizers (NPKS/NPK/NPS/NP)

Target 2.4

Promotion of sustainable farming practices, development of new fertilizer grades for increased availability of best practices in farming

Development of biologised fertilizers and probiotic feed additives

Sales of a new product – ApaSil

Development of a construction investment project for the production of feed phosphates and food grade technical orthophosphoric acid

Target 13.1 and 13.2

Target 15.1

Soil safety, biodiversity conservation, fertility growth and lower GHG emissions in production and throughout the product’s life cycle: from mine to plate

Research into an integrated approach to plant nutrition and N2O emissions in a grain‑grass crop rotation

PhosAgro Group’s carbon farm project in the Vologda region (13.4 kt of CO2‑eq. – volume of carbon dioxide absorbed by plant biomass per 200 ha over two years)

Cutting‑edge biologised adaptive plant nutrition systems

Target 4.4

Target 17.16 and 17.17

Implementation of a comprehensive phased programme to support sustainable agricultural practices and support young scholars in running sustainable development projects

Cooperation across a range of areas related to the climate agenda

A project to run cooperation programmes with universities

Cooperation with R&D centres to develop new products and ways of application

The Company’s innovations in fertilizer production are a sustainable development driver in agriculture and make a meaningful contribution to strengthening cooperation for food security.

PhosAgro Group seeks to ensure efficient and safe agricultural production and develops innovative fertilizers while also working hard to minimise the environmental impact of mineral fertilizer application and production. In doing so, the Company relies on Russian and international experience and leading research and production practices.

Our Strategy to 2025 envisages efforts to increase the share of innovative products, develop technology and production, and ramp up potential for cooperation with stakeholders and partners in the area of innovation and research.

Another important focus under this strategy is to ensure efficient production and its compliance with high standards for environmental responsibility, circular economy principles, and safety.

Our innovation, product development, and research and education management system is seamlessly integrated into the overall management framework covering all Company processes.

PhosAgro Group runs the Samoilov Scientific Research Institute for Fertilizers and Insectofungicides (NIUIF), Russia’s only institute specialising in this area.

PhosAgro Innovation Centre was established in 2018 to create cutting‑edge products and technologies in partnership with research institutions in Russia and abroad. The NIUIF and PhosAgro Innovation Centre bring together world‑class researchers, engineers, and experts from various areas to address the most complex operational issues as well as applied and fundamental research problems.

The Group actively cooperates with the Ministry of Agriculture, the Russian Academy of Sciences, federal research centres, universities, innovation funds, and international R&D organisations (University of Belgrade and Brazil’s Federal University of Lavras), along with recognised international organisations with a view to providing broad support to humanitarian and research‑intensive projects.

Research and education fall within the remit of the Technical Development Department and are discussed at the meetings of the Strategy and Sustainable Development Committee of the Board of Directors. These matters are subject to an annual review by the Board of Directors.

Among other things, the following strategic risks affect our research and educational objectives:

For more information, see the Strategic Risks section

Risks specific to the Company’s operations:

Improvement of ore extraction and processing

In 2023, to enable the mining of a block pillar under the Saami pit (Murmansk region), a project was developed to divert the Gakman and Loparskaya rivers. The project provides for the establishment of a group of hydraulic structures and is aimed at preventing the risk of river pollution when developing new deposits, which is aligned with the principles of environmental responsibility and commitment to look for optimal approaches in terms of environmental and technical safety. The Company’s team developed and agreed with regulatory authorities (state environmental review and state expert review) the design documents for the facilities required to divert the Gakman River; similar design documents for the Loparskaya River are pending approval from the regulators.

Apart from that, in order to increase output, design documentation was put together for the project to develop the reserves of the Rasvumchorr Plateau deposit through underground mining, which provides for a diversified use of coolants at the main ventilation and hot‑air heating unit. The use of liquefied natural gas at the Rasvumchorrsky mine will help reduce emissions of pollutants and GHG.

Energy and elements of circular economy

Improving the efficiency of using resources, including water, and increasing the energy efficiency of production processes are crucial tasks for PhosAgro.

In 2023, we implemented a project to increase the hourly loads of process systems by introducing a set of measures to upgrade the production of wet‑process phosphoric acid, which made it possible to reduce consumption of raw materials and energy resources across industrial sites.

Measures were also put in place to improve the reliability of ammonia production units and units No. 1, 2 and 3 of the Cherepovets site, with recommendations developed on how to improve the planning efficiency considering major overhauls amid an increase in working time.

In addition, the Balakovo site is running a project to set up an exhaust gas turbine to generate its own electricity using waste energy (sulphuric acid production steam).

The Company pays special attention to the recycling of waste and by‑products and remains on the lookout for new opportunities to utilise them as feedstock. During 2023, research and engineering efforts were completed for the Volkhov branch to develop formulations of popular NPS fertilizer grades and set up their commercial production involving the mother liquor (by‑product) of water‑soluble MAP production. The Balakovo branch developed and implemented a process for the conversion of phosphogypsum and fluosilicate acid to obtain a solution of ammonium sulphate and technical calcium fluoride, which makes it possible to utilise the by‑product of phosphoric acid production.

During the year, the Volkhov branch engaged in research and engineering efforts to develop technologies and set up new production facilities to make high‑grade phosphates, including water‑soluble phosphate fertilizers (monoammonium phosphate and monopotassium phosphate) and feed phosphates. PhosAgro also developed measurement methods for feed phosphates and food grade phosphoric acid.

PhosAgro Group’s product mix comprised 58 grades of agrochemicals of all types in 2023. By 2030, the Company plans to gear up for the introduction of 46 new own products and 24 partner products, which will include biological decomposers of organic matter, fertilizers, crop protection products; mineral fertilizers with controlled and prolonged release, liquid and solid fertilizers with microelements; feed additives with non‑protein nitrogen sources and biological components; growth enhancers, adaptogens, and amino acids. The overall focus of these developments is biologicalisation of agriculture and reduction of the environmental impact of chemicals in intensive farming, which will bolster crop yields and improved quality, while also mitigating climatic and environmental impact.

To this end, the Company is constantly exploring new solutions for the manufacturing of popular products, among other things in response to the drive for import substitution for some of the most common products.

As part of our import substitution efforts in 2023, we developed key technical solutions to produce liquid SO2. In addition, initial data was made available for the construction of a unit manufacturing food grade and technical grade purified phosphoric acid in the Volkhov branch. The Company is also working on an investment project for a construction site for feed phosphates and food grade orthophosphoric acid.

The Company’s team proposed a solution for the reconstruction of the ammonia refrigeration cycle in the third ammonia production line at the Cherepovets site to increase ammonia production in the warm season.

On top of that, we developed an energy‑saving technology for the production of complex granular fertilizers (NPKS/NPK/NPS/NP), which boasts high capacity per unit and is designed for the upgrade of existing and creation of new production facilities at the Cherepovets site and in the Balakovo branch (for that, Russian patent No. 2805234 was obtained).

INNOVATIVE DEVELOPMENTS OF JSC “NIUF”

Our long‑standing efforts in the development of sulphuric acid production were recognised in 2023, with the NIUIF team nominated for the Russian Government’s 2023 Award in science and technology.

Since 2001, NIUIF, which is part of Apatit, has developed, patented and improved an intensive domestic energy‑saving and eco‑friendly technology to make sulphuric acid from sulphur using the Double Contact Double Absorption (DCDA) method (Russian patent No. 2201393 dated 18 September 2001, Eurasian patent No. 028058 dated 10 March 2017). In 2001–2023, Russian‑made sulphuric acid systems with high capacity per unit were designed, built and put into operation at facilities across Russia and the CIS countries.

Lessons learnt from the operation of sulphuric acid systems that rely on our technology, combined with actual levels of resource consumption, production of power‑generating steam, and pollutant emissions (which are in line with both Russian and European BAT), have proven the solution’s strong competitive edge as compared to technologies offered by leading international engineering companies.

Since 2018, Apatit’s sites have faced the need to build sulphuric acid systems of significantly greater capacity, i.e. in excess of 1 mtpa of H2SO4 per year. As part of Russia’s focus on import substitution, NIUIF leveraged its track record in constructing and operating domestic sulphuric acid production systems and developed a comprehensive package of technical, design, and engineering documentation for the customer (Apatit) to erect the first ever Russian sulphuric acid system with mega capacity of 1.1 mtpa of H2SO4 per year, or 3.3 kt of H2SO4 per day.

This technology features extensive reliance on Russian‑made equipment, which has already proven reliable and delivering strong process performance in existing sulphuric acid systems.

In addition to certain technical solutions contributing to project reliability and operability in a considerably wider range of conditions as compared to foreign peers, the new sulphuric acid technology is based on a short, environmentally friendly, and energy‑saving DCDA process. To name its competitive advantages, the new process scheme for sulphuric acid:

- quickly reaches design capacity;

- is reliable and easy to operate;

- guarantees minimal exhaust of harmful gases into the atmosphere;

- has minimum power consumption levels;

- is fitted with simple and reliable equipment;

- has an SO2 conversion rate of 0.9980 and above;

- has a total SO3 absorption rate of 0.9999;

- generates high‑pressure steam (40 atm) to produce electricity;

- has reserve capacity available.

Another major area of related efforts is NIUIF’s R&D project run jointly with the Kirovsk‑based Geological Institute of the Kola Science Centre of the Russian Academy of Sciences to identify natural diatomite in Russia suitable for the domestic production of high‑performance vanadium sulphuric acid catalysts. These efforts bore fruit as the exploration team discovered lake deposits of natural diatomite on the Kola Peninsula, which were deemed fit for obtaining high‑performance catalysts. Currently, NIUIF is looking into options available to mine and prepare diatomite for subsequent use. Lake deposits have high‑quality reserves sufficient to sustain production of catalysts for 40 years.

Development of new fertilizers

Development of biologised fertilizers

In 2023, PhosAgro Group, together with the Russian State Agrarian University – Moscow Timiryazev Agricultural Academy, conducted second‑year enhanced tests of the impact of mineral fertilizers and their biologised counterparts on the carbon footprint of products. The carbon footprint of crop production includes nitrous oxide emissions from soil resulting from nitrogen conversion processes in mineral and organic fertilizers, as well as carbon emissions from plant respiration, decomposition of crop residues and straw, and mineralisation of soil organic matter (including humus). Thus, tests with biologised counterparts at comparable fertilizer doses demonstrated higher crop yield per hectare and a smaller carbon footprint per unit of agricultural products.

The tests also helped obtain data on actual GHG emissions vs standard levels of soil nitrogen and carbon loss. This data can be used for the reduction of the carbon footprint of agriculture and carbon accumulation in soil, among other things through the application of new eco‑friendly biologised mineral fertilizers. On top of that, the tests clearly showed that the rate of 1% set in Russia for nitrogen losses induced by mineral fertilizer application is significantly overestimated.

In 2024, there are plans to clarify the data available and to conduct a detailed analysis of the processes of nitrogen and carbon transformations in soil in order to achieve intensified accumulation of humus in arable land.

Other innovative products

Manufacturing and sales of the new product – ApaSil

In 2023, the Company continued to develop and sell products with innovative features. As one example, the ApaSil adaptogen was placed on the market, with over 5.1 t already supplied to farmers. The product is designed for seed pre‑treatment and foliar application on a wide range of agricultural crops and ornamental plants. Field trials in different regions and on different crops have shown that ApaSil helps plants cope with the stresses associated with drought and diseases.

In 2023, the results of scientific tests have been confirmed by PhosAgro Group’s customers.

In 2024, the process method will be patented, with plans to register ApaSil in foreign markets.

Development of probiotic feed additives

In 2023, PhosAgro teamed up with the Skryabin Moscow State Academy of Veterinary Medicine and Biotechnology to run an experiment on laboratory animals to determine the effectiveness of cutting‑edge probiotics against the main pathogens that cause intestinal diseases in the young stock of farm animals. New MAP‑based additives will help improve the health and productivity of animals while reducing the intake of antibacterial drugs. Initial results show that animals demonstrated increased survival when new additives were used.

In 2024, prototypes of probiotic feed additives are planned to be tested on young cattle in farm settings.

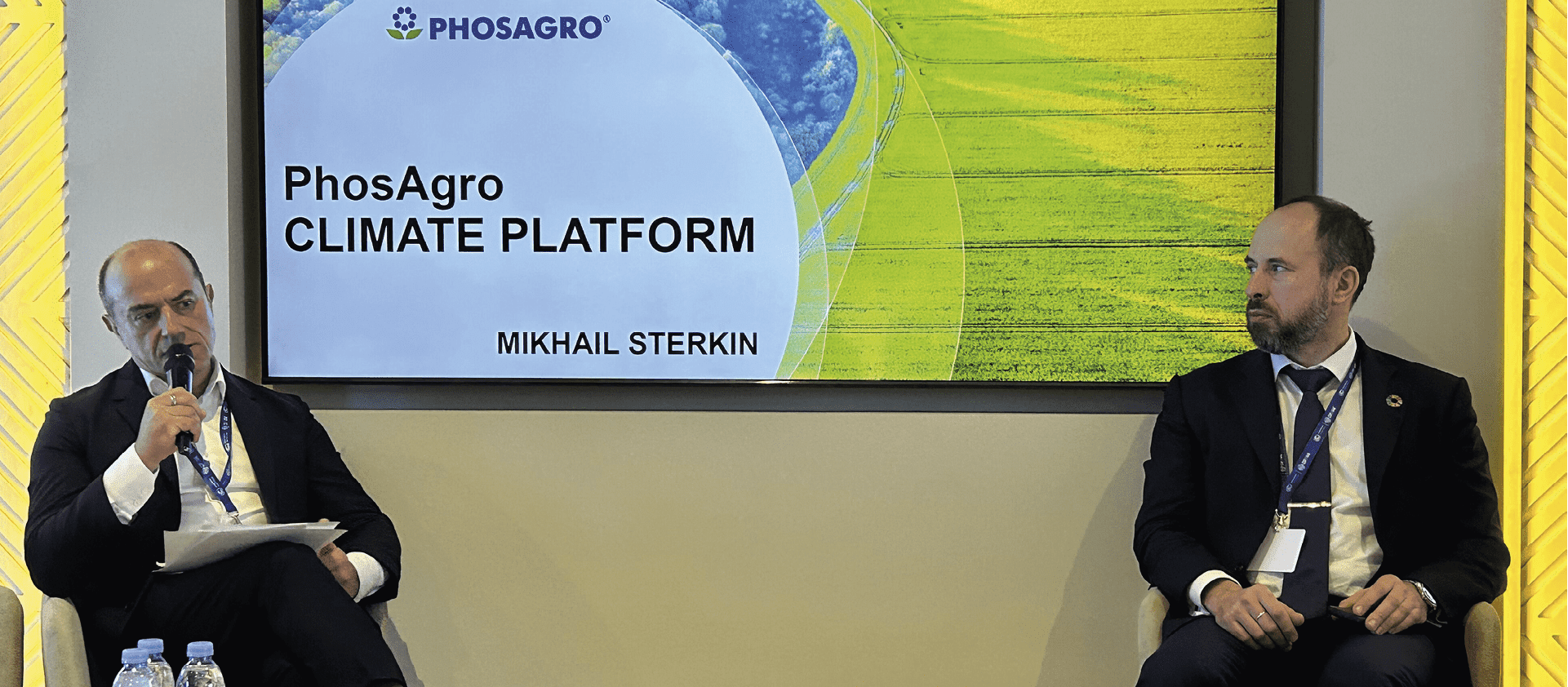

Research as part of PhosAgro’s carbon farm project in the Vologda region

As part of a long‑term climate action, in 2022 the Company set up a carbon farm to study CO2 compensation and absorption of carbon emissions by various ecosystems, as well as to test hands‑on solutions for establishing large‑scale carbon farms in agriculture and forestry.

In the Cherepovets and Vologda regions, in 2022 we set up 100 ha trial stations 100 km away from each other to study carbon sequestration abilities of perennial forage grasses cultivated in industrial conditions using a variety of fertilization schemes. In the Vologda region, forage grasses are the basic crop with the greatest GHG absorption potential.

The project’s priority objective is to accumulate knowledge and expertise in cooperation with the research community and study CO2 absorption by various crops (forage grasses, grain cereals and pulse crops), young coniferous and deciduous forests, and agricultural sites with varying organomineral nutrition regimes.

In 2023, we continued tests at 24 forest areas within the carbon farm, planting additional 10 thousand coniferous and 15 thousand coniferous young seedlings to compensate for those that failed to survive the winter.

Preliminary research done by the Centre for Forest Ecology and Productivity of the Russian Academy of Sciences shows that ecosystems of this kind can achieve average annual carbon stock of 14.6–16.0 t of CO2‑eq. per ha over a period of 25 years.

Two years of tests run by the Vereshchagin Vologda State Dairy Farming Academy show that estimated levels of carbon dioxide absorption by the aboveground plant biomass on an area of 200 ha are 5,475 t of CO2‑eq., resulting in accumulation of 7,925 t of CO2‑eq. by the belowground plant biomass.

Taking into account the processes of soil respiration, humification and humus mineralisation, these results suggest that soil stores 1,050 carbon units with an average annual gain rate of 2.6 t of CO2‑eq. per ha, which can be verified in actual farming environments by using the most common methods of tests for soil carbon.

The carbon farms used only PhosAgro Group’s mineral fertilizers and did not rely on organic fertilizers, green mass, or other methods to build soil carbon.

Forage grass trials were conducted on a 20‑hectare plot at PhosAgro’s carbon farm in 2023:

- Agricultural technology 1: ryegrass + clover + festulolium;

- Agricultural technology 2: ryegrass + clover + alfalfa;

- Agricultural technology 3: ryegrass + clover + bird’s‑foot trefoil;

- Farm’s practice: ryegrass + clover

As part of the project, PhosAgro and the Russian State Agrarian University – Moscow Timiryazev Agricultural Academy are also running a series of tests in grain‑grass crop rotation at the farming station for different types of fertilizers with the return of plant residues to soil. Results obtained so far suggest that it is a combination of mineral and organic fertilizers with regular liming that allows for the most effective carbon gain in soil during the crop rotation period (five years).

These studies show that a balanced approach to crop rotation and application of fertilizers and ameliorants not only deliver a good yield of winter wheat of 5.5–6.0 t per ha in the Vologda region but also, subject to the return of plant residues to soil, achieve carbon gain by soil of 2.8 t of CO2‑eq. per ha per year even without organic fertilizers; when organic fertilizers are used, the efficiency of the carbon gain process increases to 5.2 t of CO2eq. per ha per year. The data demonstrate that with an increase in the dose of mineral fertilizers, subject to properly organised processes, the carbon footprint of agricultural products will be decreasing.

In 2024, PhosAgro plans to refine and analyse all data and, jointly with the Izrael Institute of Global Climate and Ecology (IGCE), develop methods for various agricultural crops, ornamental plants and forest crops and have them rolled out for practical application by farmers.

Cutting‑edge biologised adaptive plant nutrition systems

In 2023, experts from the Company and the Federal Williams Research Centre of Forage Production and Agroecology ran a production trial in the Moscow Region to cultivate forage crops using biologised adaptive plant nutrition systems and a biological preservative for forage conservation.

As opposed to the routine alfalfa cultivation using

The application of Fermasil developed by Innopraktika along with the biologised adaptive plant nutrition system resulted in improved quality and nutritional value of forage while offering the same storage life. The trial involved analysing both the carbon footprint of the products and their qualitative properties. The results showed an increase in the levels of lactic and acetic acids, contributing to the prolonged preservation of the feed’s high quality. The level of succinic acid, which is an indicator of feed spoilage, remained within acceptable limits.

Thus, the new types of fertilizers developed by PhosAgro help agricultural producers increase crop yields despite the constraints of limited land resources while also improving forage quality, reducing carbon footprint, enhancing soil fertility, and increasing production margins.

Our strategy for innovating and helping students, teachers and farmers to develop profession competencies relies on partnerships with the leading agricultural universities and R&D centres

RUSSIAN SCIENCE, EDUCATION AND AWARENESS RAISING PROJECTS

Russian Academy of Sciences

Russian Academy of Sciences Cooperation across a range of areas related to the climate agenda and low‑carbon transition plan

- The carbon farm project progressed into its second year with additional tree seedling planting and procurement of necessary equipment

- 15 research organisations participated in the development of new fertilizers and feed additives, completing a total of 20 research projects

- Further progress was made in implementing other projects involving leading Russian scientists to develop and promote innovative products:

- biotechnologies and feed additives developed

- registration process for new biologised mineral fertilizers launched

- a pipeline of new promising projects built

Creating PhosAgro Group’s nationwide educational network across 30 agricultural universities in Russia

- The number of educational centres expanded to 17, including two flagship multifunctional centres in Moscow at the Russian State Agrarian University – Moscow Timiryazev Agricultural Academy and Skryabin Moscow State Academy of Veterinary Medicine and Biotechnology

- PhosAgro’s open educational centres hosted an array of activities, including daily lectures, additional professional education courses, open days with major employers, meetings for young scientists, conferences, and recorded lecture demonstrations

- Lecture topics spanned a broad range of subjects, including agrochemistry, agronomy, crop production, innovation and digitalisation in agriculture, economics, law, and sustainable farming

- Plant trials, including as part of diploma projects, were conducted at four phyto‑classes of PhosAgro educational centres

- Career guidance activities for schoolchildren were implemented jointly with professors from the Russian State Agrarian University – Moscow Timiryazev Agricultural Academy

- Efforts were underway to develop 15 innovative additional educational courses covering various subjects and providing an opportunity to earn PhosAgro certificates and official state qualifications

- The Company continued to develop the Pro Agro Lectorium educational online platform and implement it across all agricultural universities

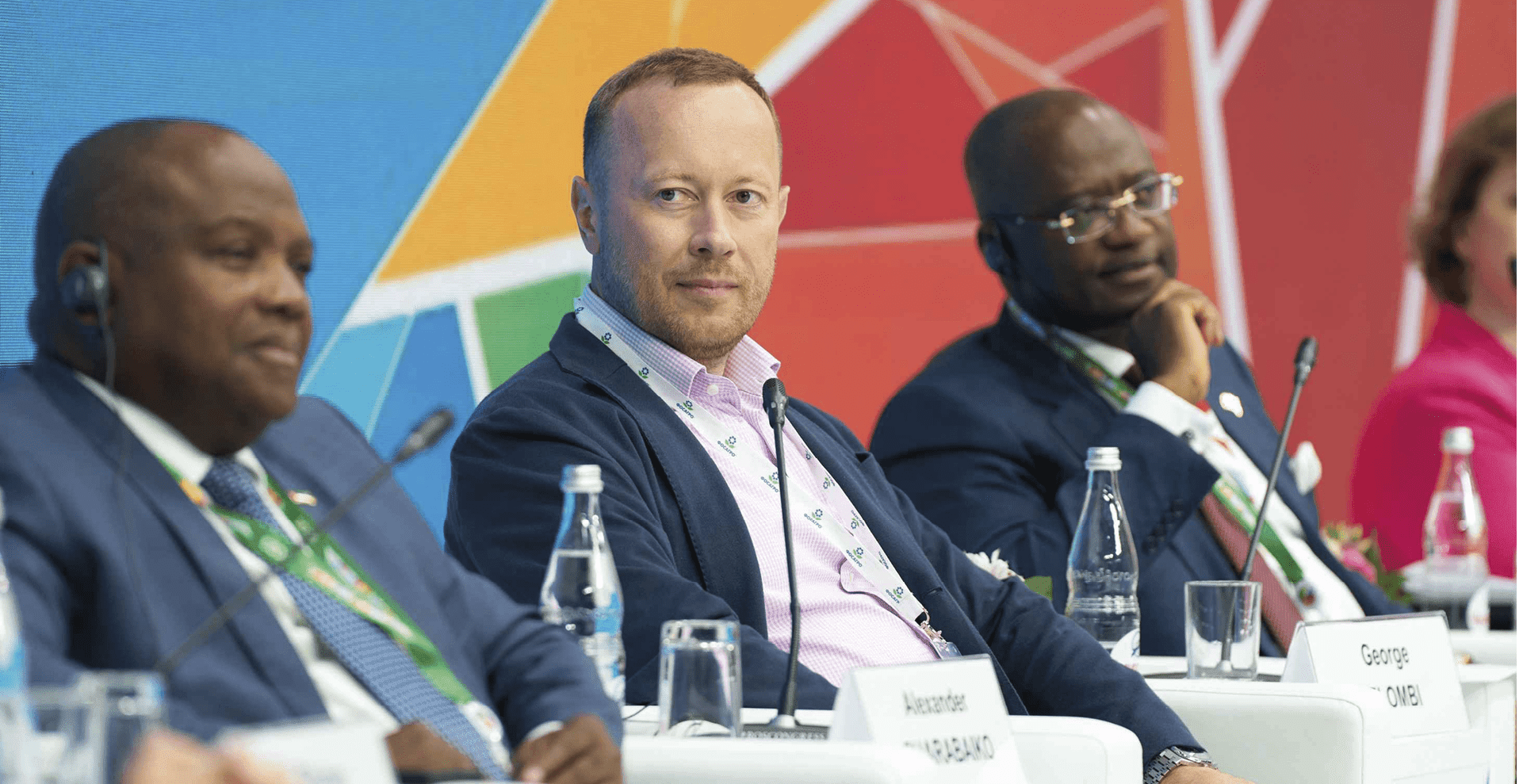

International science, education and awareness raising projects

Green Chemistry for Life, a joint grant programme by PhosAgro, UNESCO and IUPAC

Financial support and scientific guidance for young scholars doing research in emerging Green Chemistry technologies to address environmental challenges and ensure sustainable use of natural resources

UNESCO‑Russia Mendeleyev International Prize in Basic Sciences

The international prize aims to foster scientific progress, science popularisation and international cooperation. It also serves as a tribute to the renowned Russian scientist Dmitri Mendeleyev, who devised the periodic table of the elements, playing a pivotal role in the future of chemistry, physics, biology, astronomy, and geochemistry

- As part of the seventh round of the grant programme, PhosAgro, in partnership with UNESCO and the International Union of Pure and Applied Chemistry (IUPAC), awarded eight grants to young scientists from Armenia, Italy, Brazil, Vietnam, Malaysia, Tunisia, Croatia, and South Africa. Over the course of seven rounds of the programme, more than 900 applications from young researchers across 120 countries were submitted, with grants awarded to 48 scientists from 32 countries.

- PhosAgro Group proudly served as a partner for the UNESCO‑Russia Mendeleyev International Prize in Basic Sciences. The prize is the only award granted for sustainability‑focused research in fundamental sciences under the auspices of UNESCO.

Summer Schools on Green Chemistry project run jointly by PhosAgro, IUPAC and Green Sciences for Sustainable Development Foundation

The project is an educational initiative run by the International Union of Pure and Applied Chemistry (IUPAC) with the support of PhosAgro to improve the qualifications of young scholars engaged in green and innovative chemistry research globally with a view to promoting innovations and breakthroughs

- The sixth session of the IUPAC Summer School on Green Chemistry took place at Ca’ Foscari University of Venice, Italy. It brought together 150 young scientists and 30 leading teachers from 44 countries, including 48 African researchers

- 2023 saw the sixth session of the IUPAC Summer School on Green Chemistry supported by Phosagro. Since inception, it has attracted the participation of over 800 young researchers and 60 teachers from 75 countries

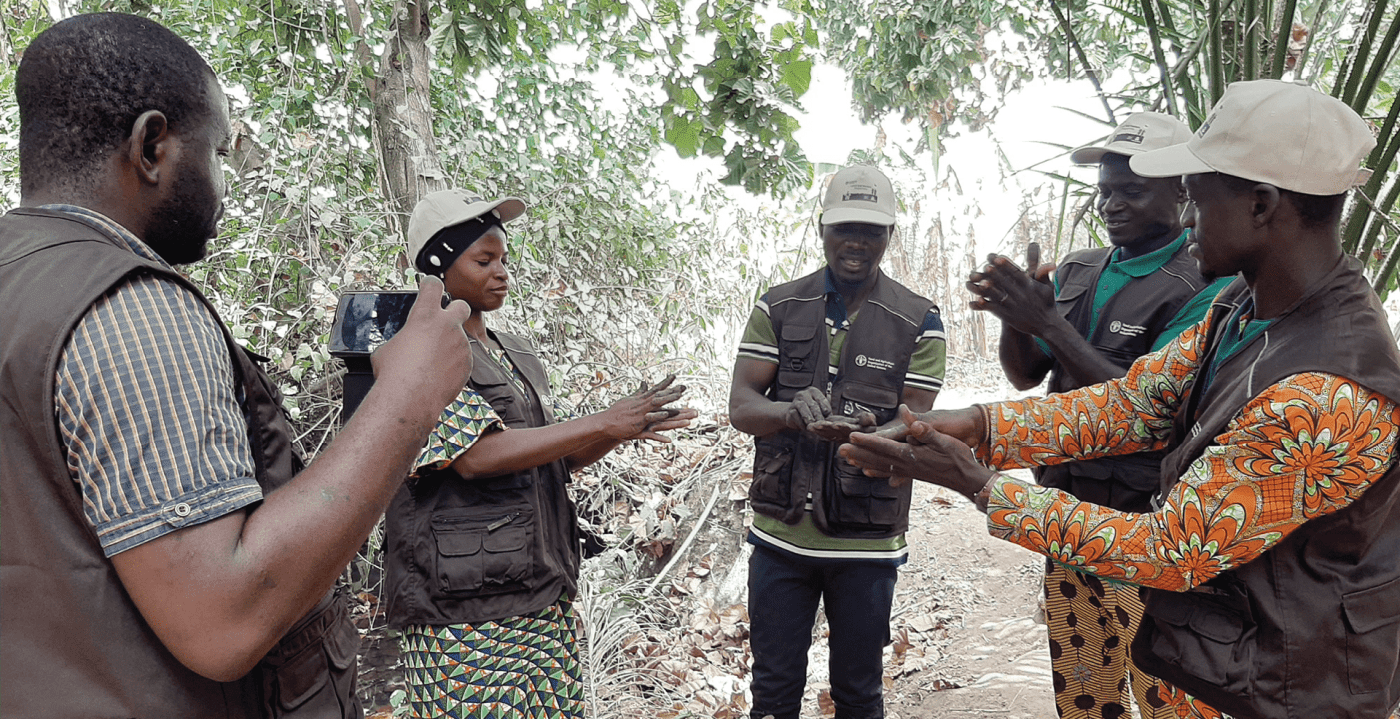

UN Food and Agriculture Organisation (FAO)

UN Food and Agriculture Organisation (FAO) Development of Sustainable Agriculture through the Implementation of the Global Soil Doctors Programme and the Creation of the Global Soil Laboratory Network (GLOSOLAN)

Promoting sustainable soil management among farmers and expanding the Regional Soil Laboratory Network (RESOLAN) in Africa, Latin America and the Middle East; achieving environmental and social well‑being by raising awareness of soils to inform sustainable farming decisions

- PhosAgro supports the FAO Global Soil Partnership in implementing the project to advance sustainable agriculture and set up the Global Soil Laboratory Network. Currently, the global network comprises over 800 laboratories across 150 countries

- PhosAgro supported the establishment of the International Network on Soil Fertility and Fertilizers (INSOILFER), which aims to promote sustainable soil and fertilizer management with a view to increasing crop yields, as well as the International Network on Soil Pollution (INSOP).

Development of scientific and educational cooperation with African countries

Development of scientific and educational cooperation with African countries PhosAgro’s sponsorship and expert contribution to building Africa’s food sovereignty and expanding scientific and educational cooperation between Russian and African universities and agricultural associations

Development of scientific and educational potential of African countries, along with the training of qualified personnel for the agricultural and chemical industries to build Africa’s food sovereignty

- During the Second Summit Russia–Africa Economic and Humanitarian Forum, PhosAgro introduced its Pro Agro Lectorium, a digital educational platform for agricultural professionals in African countries to learn more about advanced and effective farming practices.

- As part of the Second Summit Russia–Africa Economic and Humanitarian Forum, several bilateral and trilateral agreements were signed between Russian and African educational institutions and PhosAgro. These include: an agreement between PhosAgro, the Mendeleyev University of Chemical Technology and Assiut University (Egypt); an agreement between PhosAgro, the University of Zambia, and the Russian State Agrarian University – Moscow Timiryazev Agricultural Academy; an agreement between PhosAgro and Makerere University (Uganda); an agreement between PhosAgro and Ahmed Baba University (Mali); an agreement between PhosAgro and Injibara University (Ethiopia)

Institute of Chemistry and Sustainable Development at the Mendeleyev University of Chemical Technology

Institute of Chemistry and Sustainable Development at the Mendeleyev University of Chemical Technology Partnership in promoting basic sciences and research in chemistry and related fields to further sustainable development globally

- Promoting basic sciences and research in chemistry and related fields to further sustainable development globally

- Articulating an expert point of view on major issues on the global sustainability agenda

- Implementing joint programmes and projects

- Organising joint events to promote research in green chemistry

- Supporting young scholars engaged in innovative research in green chemistry, unlocking their scientific potential, strengthening cooperation between them and involving them in joint research projects

- PhosAgro awarded scholarships to 20 winners of the third and fourth competitions of the Laverov scholarship programme established for young scientists from the Mendeleyev University of Chemical Technology who do research in ecology, environmental management, new materials and substances. Winners were selected based on their academic achievements, scientific publications in high‑ranking journals, and their interest in developing projects in the field of green chemistry.

- PhosAgro‑funded scholarships named after academician Nikolay Laverov were awarded to 40 talented university students and postgraduates

- In order to develop students’ professional knowledge of innovative processes in green chemistry and related fields, PhosAgro Group partnered with the Institute of Chemistry and Sustainable Development to organise a series of webinars for Bachelor’s and Master’s Students at the UNESCO Chair of Green Chemistry for Sustainable Development at the Mendeleyev University of Chemical Technology. The focus areas were aligned with the UN 17 Sustainable Development Goals

United Nations Global Compact

United Nations Global Compact As a Global Compact Lead company, PhosAgro contributes to the initiative by providing expert advice on a wide range of topics

- The Global Compact Lead status makes it possible to engage in the discussion of the international agenda while actively liaising with other international organisations and contributing to the development of new business approaches, regulations and standards globally

- Contributing to the UN Sustainable Development Goals through projects implemented by the Company as a responsible producer of environmentally friendly mineral fertilizers

- Enhancing global partnerships for sustainable development

- Articulating an expert point of view on major issues on the global agenda

- Participating in global initiatives aimed at addressing today’s global challenges

PhosAgro joined the UN Global Compact’s Forward Faster initiative calling for an accelerated achievement of the UN Sustainable Development Goals (SDGs)

The initiative launched during the United Nations General Assembly seeks to bring together the efforts of social responsibility leaders worldwide. As a participant in the Water Resilience Coalition, a UN Global Compact platform, PhosAgro will contribute to a faster achievement of SDG 6 (Clean Water and Sanitation) covered by the Forward Faster initiative, by advancing sustainable water resource management

- We retain our status of a Global Compact Lead company and are actively involved in the alliance’s initiatives. This enhances PhosAgro’s business reputation globally, reinforces its competitive strengths and increases public trust in PhosAgro, while also helping to boost existing and forge new partnerships

- PhosAgro Group supported the open call by the business community to safeguard water resources under the auspices of the United Nations. The Forward Faster initiative was presented during the UN Water Conference and was developed in collaboration with the Water Resilience Coalition, a UN Global Compact platform, alongside the CEO Water Mandate. PhosAgro stands as the only Russian participant in the Forward Faster initiative focused on achieving SDG 6 (Clean Water and Sanitation)

- PhosAgro took part in the panel discussion “Food Security in a Changing Climate: Global Challenges and Opportunities” during the 28th session of the Conference of the Parties (COP28) to the UN Framework Convention on Climate Change

The Diplomatic Academy of the Russian Ministry of Foreign Affairs

The Diplomatic Academy of the Russian Ministry of Foreign Affairs Partnership in scientific research with a focus on sustainable development and green economy

- Advancing research in sustainable development and carbon‑neutral green technologies

- Collaborating on green programmes and projects

- Supporting major national, regional, and international initiatives promoting the UN Sustainable Development Goals

- Organising events addressing food security, environmental protection, and human health

- PhosAgro, in partnership with the Diplomatic Academy of the Russian Ministry of Foreign Affairs and with support from the FAO Liaison Office with the Russian Federation, organised an international forum‑webinar titled “Protecting the Planet’s Soils from Degradation and Depletion. International Experience in Maintaining Soil Fertility and Health”. The forum attracted more than 350 scientists and experts from Russia and Latin America, Africa, Europe, and Asia

European Sustainable Phosphorus Platform (ESPP)

European Sustainable Phosphorus Platform (ESPP) Partnership on the European political, scientific and technical agenda for the sustainable use of phosphate resources

- Fostering knowledge exchange, experience transfer and professional networking in phosphorus management; promoting dialogue between market participants, stakeholders and regulators

- Removing regulatory barriers

- Effecting communication through newsletters, website, conferences and publications

- PhosAgro Group participated in the European Sustainable Phosphorus Conference that brought together several hundreds of representatives of business, stakeholders, regional and national authorities. At the event, we presented our best practices of phosphogypsum application in road construction